PTR- Precured Tread Rubber

PTR- Precured Tread Rubber

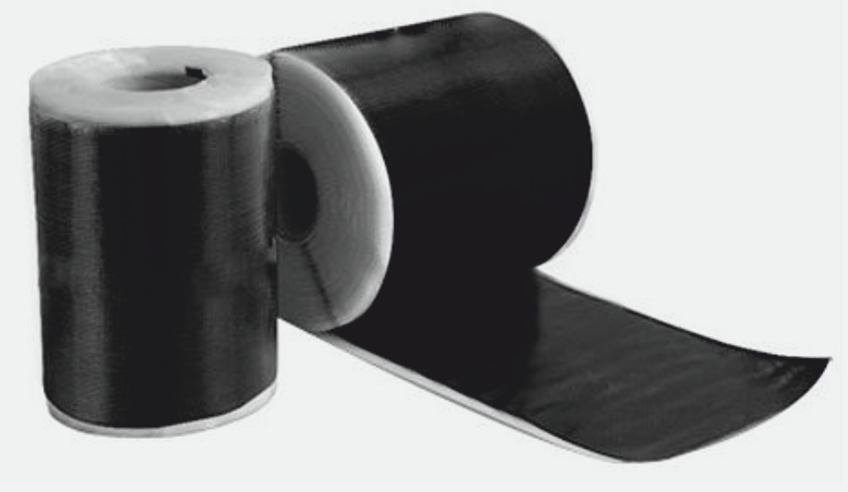

Pre-cured tread rubber(PTR) is a vulcanized rubber belt molded in a particular design pattern with a specified width, thickness & weight, suitable to perform on a given road application such as long-haul, short-haul, hilly terrains, and mines.

PTR rubber has two key aspects to it, first is the chemical composition of rubber compound and second is the design pattern. The chemical composition of a mine tread rubber is very different from that of hills, similarly the design pattern for short-haul might vary from the design pattern for a long-haul application. It is of paramount importance to understand the vehicle application before choosing the right tread, the right choice takes into consideration the type of vehicle, tyre axle, tyre type and road application.

INDAG manufactures the best quality retreading materials with meticulous attention to the details. We have the best manufacturing processes and management systems in place, well recognized and certified by world's most reputed organizations.

Reference to our certifications- SWISSCERT- ISO 9001:2015, ISO 14001:2015.